Quality control of precision parts

Precision metal parts

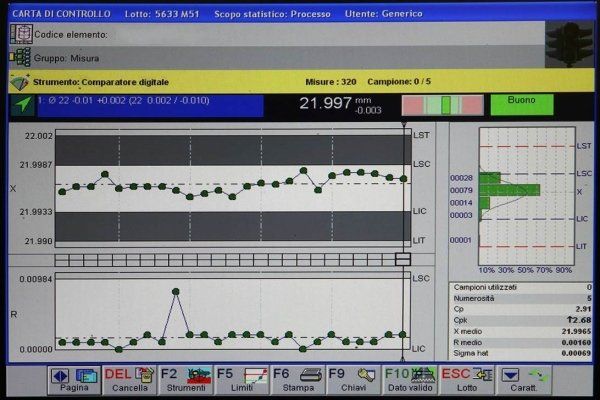

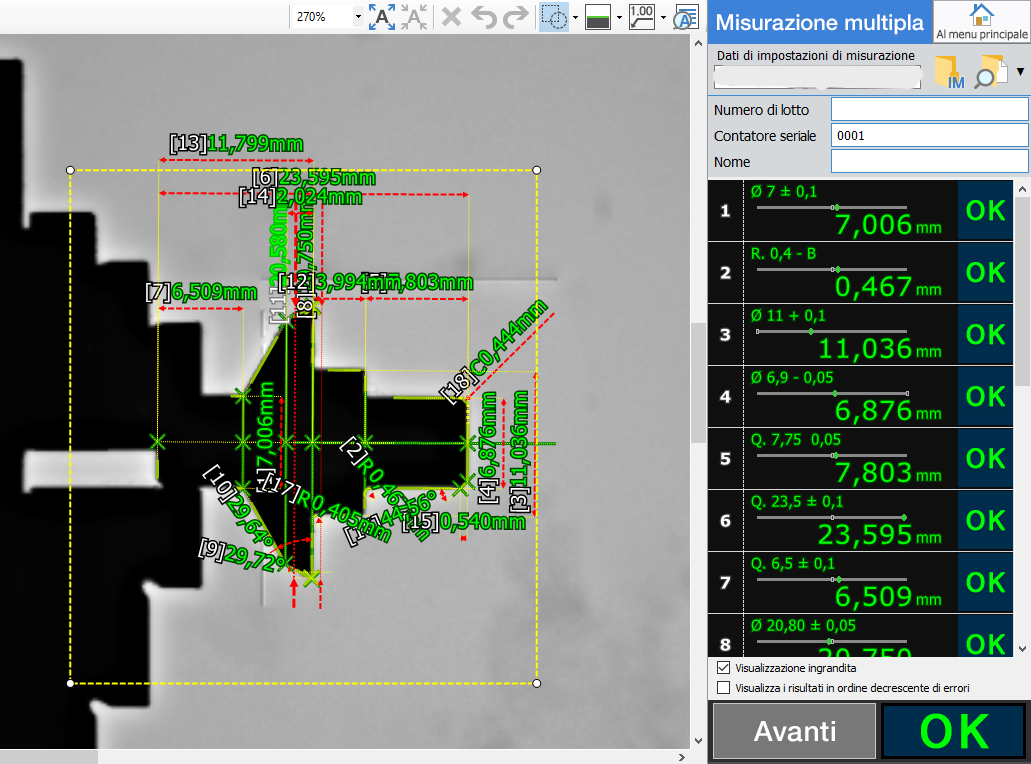

Famit is equipped with a wide range of digital measuring instruments and control gauges, an SPC measuring station, 2 profile projectors, 1 roughness tester, and 1 Keyence IM – 8030 T optical measuring machine, fitted with a spindle and probe capable of ensuring control over components with the most complex profiles.

Sampling and inspections

Since 1984, Famit has produced in accordance with the requirements of the automotive industry through documentation and archiving of process controls, as well as the traceability of each production batch down to the individual packaging label.

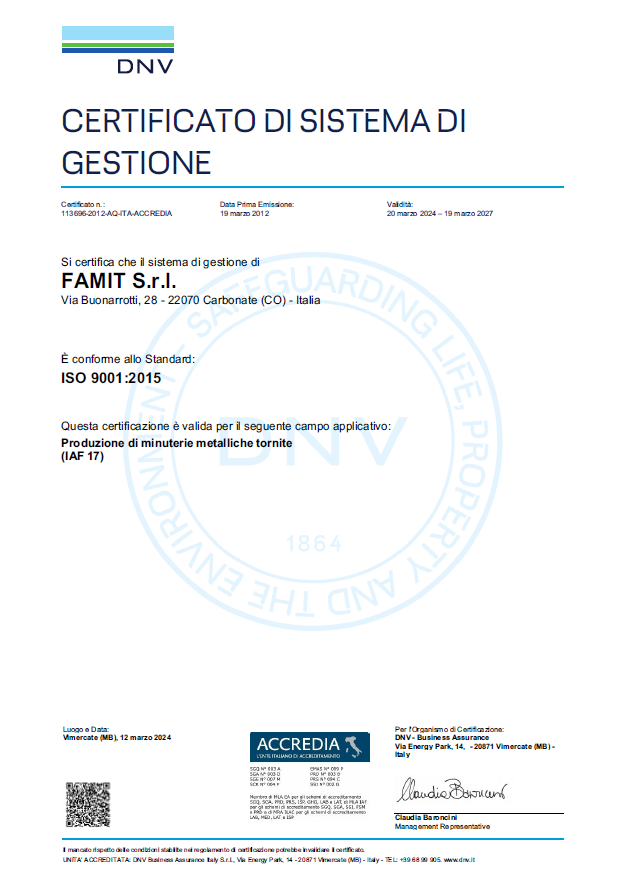

Certification, obtained in 2000, is currently ISO 9001:2015 issued by D.N.V Italian s.r.l. (n.cert. 05973 – 2000 AQ MIL SINCERT), which attests to the operational condition of the company’s system capable of satisfying and maintaining increasingly high market demands over time.

This philosophy encompasses the entire company system, from maintenance plans for machinery to staff training.

Each production batch is controlled either by attributes or by variables according to predefined or customer-requested sampling plans, analysing machine and process capability data (CPK – CMK).

Contact us

Request a quote for the creation of customised metal turning services